There is far more to being a distributor of Power Equipment’s brands than simply making sure the customer receives their engine. Testing and customising engines and equipment are among the many vital tasks happening at its workshop facility in Melbourne, Australia – tasks that set Power Equipment far and above its competitors in the engine distribution game.

Like most good engineering, the best systems usually look to be doing everything with ease. Invariably however, there’s a lot going on behind the scenes. The same can be said for Power Equipment through its main workshop facility at head office in Melbourne, Australia.

Perhaps best described as the “pumping heart” of the operation, Power Equipment’s workshop is one of the keys to its leading abilities in distribution of the best marine and industrial engine brands in the world.

“We’re far more than a ‘box in, box out’ distributor,” explains Nick Lee, National Operations and Engineering Manager for Power Equipment.

“Unlike most of our competitors, we know our products inside and out,” Nick says, “and we pride ourselves not just on having that knowledge, but sharing it.”

Nick oversees the workshop team at Power Equipment and knows where quality starts in any operation.

A brief look around Power Equipment’s workshop areas is a picture of quality in itself – super clean, designated and well organised work areas and specialist equipment. Whether for testing, customising – or even just moving larger engines or equipment around safely.

Even the untrained eye can see the pride taken in the job here. Get into the detail of the people and what happens on the workshop floor and the quality delivered through that pride is revealed.

“We’re a great team here because we’ve got all the skills in-house,” says workshop fitter Paul Fenech.

“We can turn things around quickly because we’ve not only got the gear, we’ve got the people who have the knowledge, regardless of the engine,” he said.

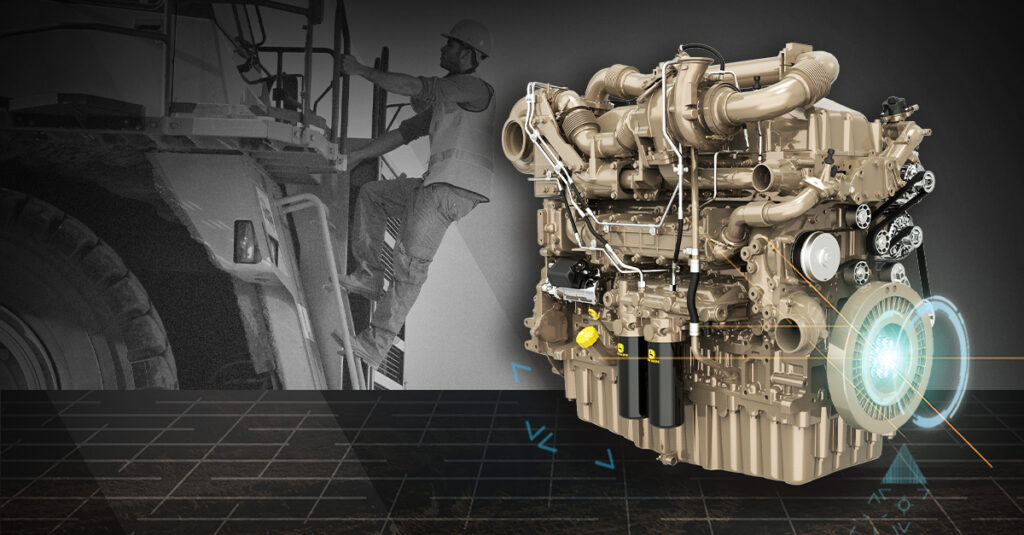

Distributing the range of engines and ancillaries that come with Power Equipment’s brands like Yanmar, John Deere, Torqeedo, Oxe, Cox, D-Torque, Mase and Gori to name a few is no small feat.

Ensuring the dealer or customer is getting exactly what they need is just one part of this feat – quality control plays an even bigger role.

“We bring everything together in the workshop before that engine goes out,” explains Paul.

“Whether that means just running tests, or complex customisation of an engine to meet a customer’s needs, it’s all done in-house.”

The workshop employs two dedicated engine test rooms where engines are put through running and alarm simulations. Nothing leaves Power Equipment unless they know it works as it should!

Depending on a customer’s requirements for engine governing, filtration, muffler systems, unique wiring harness configuration or cooling systems, Power Equipment’s workshop team make it happen.

“Preparing an engine for distribution can take anything from an hour to two or three days in some cases, depending on the complexity of the build,” explains Paul.

“Then everything is checked by a different member of the team, so our quality control is second to none.”

With (literally) thousands of engine variants and customisable options across all the brands within the Power Equipment stable, coming across something new isn’t uncommon.

“No day is the same in here,” says Paul, “but it’s never an issue if you’re confronted with an engine build or component you haven’t dealt with before, because there’s always someone here who has and we all help each other.”

Just one example of how Power Equipment’s workshop team is sharing its vast knowledge of products and engine build systems comes via some innovative use of Paul’s skills from a previous career.

“I was involved in graphic design for many years and I was asked if I could apply those skills to putting together instruction manuals for our processes in building and customising engines,” Paul said.

“So now, starting with a tablet and a series of photo’s to help explain each job, I basically document each process so that it can be passed on down the track to anyone who hasn’t done it before.”

Power Equipment’s clean and organised workshop is exceeded only by such teamwork, delivering real dividends for dealers and customers alike.

“The passion and pride in our work is second to none – it’s a great crew,” says Paul.